Yatong Plastic Recycling Crushing and Washing Line / PE PP Granulating Machine / Crushing Machine /Recycling Line

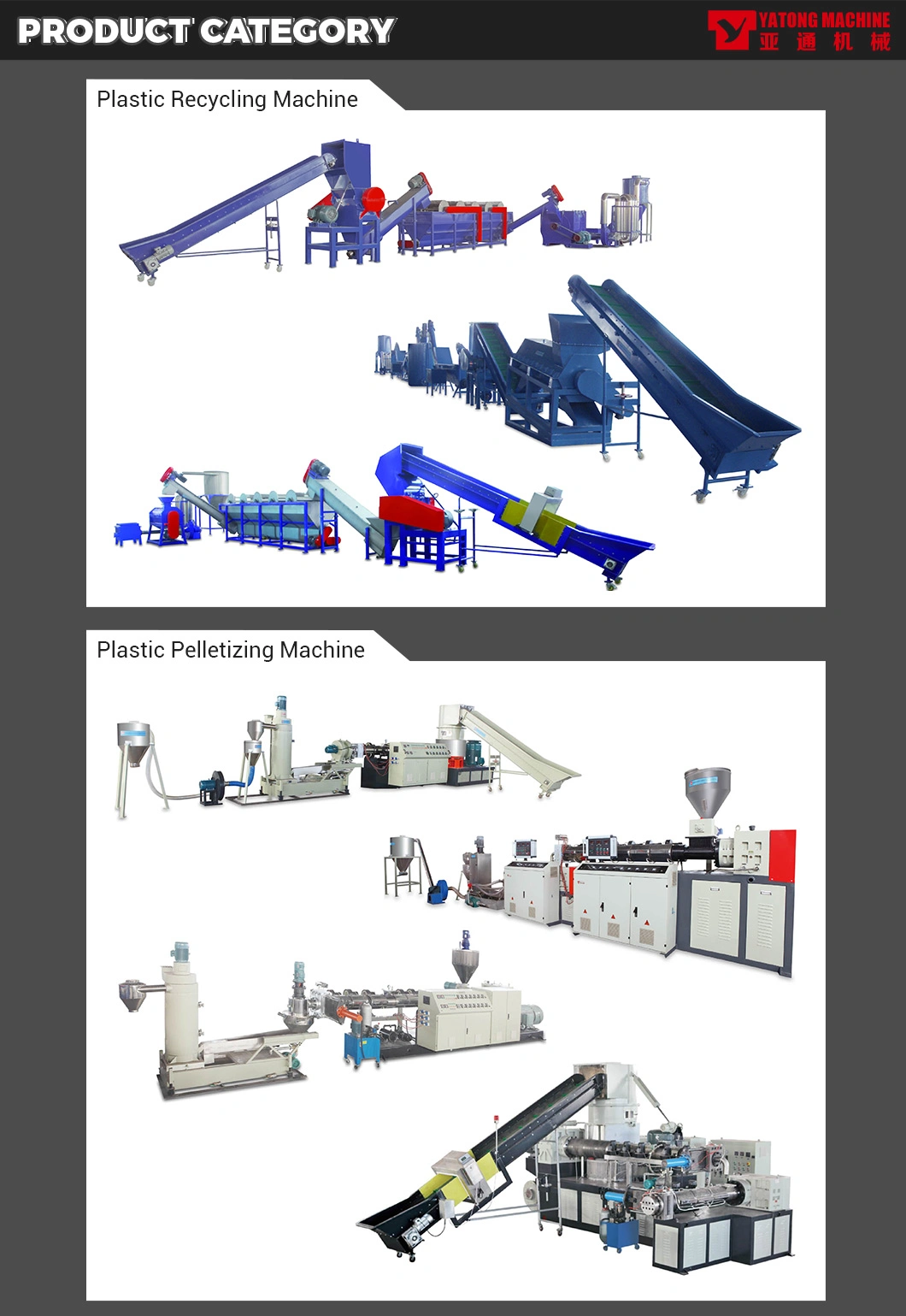

Film washing line is widely used to treat PP/PE plastic waste mixed material into clean film flakes,which include waste PP woven bags, plastic bags, plastic garbage, waste plastic mulch film. After films cleaned, you can make them to be granules with next process which is called pelletizing line.This production line is high automatic operating and save labor cost and low after maintenance. With advanced international industry concepts and technologies to meet waste plastic recycling at home or abroad. This pp pe recycling machine could be displayed "L" or "U" shape according clients' workshop.

Working Process:

| Machine List | Function |

| Belt conveyor | Convey waste plastic into crusher |

| Crusher | With water, will cut waste plastic into small piece |

| Screw Conveyor | Convey small pieces |

| Floating Washing Tank | Separate PP PE and PET, dirty according to specific density |

| Screw Conveyor | Convey small pieces |

| high speed frication washer | Scrubbing material in high speed with water |

| Screw Conveyor | Convey small pieces |

| Dewatering Machine | High speed centrifuge drying |

| Drying System | Electric heating wind drying |

| silo | Store the final material |

| Electrical Control Panel | Adopts Siemens and Schneider as main component. |

Features :

1. Final products has good quality. When process PP PE film bags, final products humidity below 5%,

2. The whole line capacity between 150kg/h-2000kg/h (150kg/h, 300kg/h, 500kg/h, 1000kg/h, 2000kg/h)

3. Parts which contact material use SUS304, thickness more than 3mm, ensure long service lift time

4. World famous brand components applied on the production line- SKF bearing, Siemens contactor, Omron temperature, FUJI invertor, Siemens PLC controletc

5. The whole production line with CE certification, ISO9001 certification

Specification :

| Model | Capacity (kg/hr) | Installed Power (KW) | Hot Washing | Water Supply (m3/hr ) | Manpower (person) | Area Required (L*W*H) |

| ME-300 | 300 | 120 | Optional | 4-5 | 2-3 | 23mx5mx3.5m |

| ME-500 | 500 | 185 | Optional | 5-7 | 2-3 | 25mx6mx4.5m |

| ME-1000 | 1000 | 270 | Optional | 8-10 | 4-5 | 40mx6mx5.5m |

| Technical Parameter | Model | YT300KG | |

| Belt conveyor | Motor power | 1.5kw | |

| Length | 4-5m | ||

| Crusher | Motor power | 37kw | |

| Crushing chamber size | 800mm*600mm | ||

| Rotation blades | 8pcs | ||

| Fixed blades | 2pcs | ||

| Blades material | 9Crsi | ||

| Crushing mesh size | Ø80mm | ||

| Capacity | 300kg/h | ||

| Friction washing machine | Motor power | 5.5kw | |

| Rotation speed | 500rpm | ||

| Length | 3000mm | ||

| Diameter | Ø250mm | ||

| Material | All elements contact with water is stainless steel | ||

| Floating washing tank | Tank length | 6000mm | |

| Floating motor | 2.2kw*2pcs | ||

| Discharge dirty motor | 1.5kw | ||

| Screw conveyor | Motor power | 2.2kw | |

| Diameter of main axis | Ø250mm | ||

| Capacity | 300kg/h | ||

| Film Dewatering machine | Motor power | 45kw | |

| Rotation speed | 1200rpm | ||

| Capacity | 300kg/h | ||

| Air blowing system with silo | Heating power | 36kw | |

| Air-inlet motor | 7.5kw | ||

| Air transportation pipe diameter | Ø219 | ||

| Silo volume | 1m3 | ||

Application : make PE PP granule then produce PE PP pipeREMARK : if the equipment or technological parameters have some change , we shall not make a notice separately .

Transportation and Packing

• For the loose cargo we will packing by wooden box

• For the full container loading we are packing the machine by film and some on pallet accordingly

• We can ship the goods by air or by sea

• We will send pictures of cargo loading to our client to check and keep recording

• We can send cargo to client's warehouse to loading

Our Services

1. Our factory provide machine testing when customer come to our factory to see this machine.

2. We provide detail machine technical specification, electric diagram, installation book, operating manual, drawings.

3. We can provide engineers to customer's factory to help installation and training workers if customer required.

4.Spare parts is available when u need.within warranty,we will provide without any charge.Over warranty,we can provide spare parts just with factory cost.We will take response and provide technical support and repair of the whole machine lifetime.

YATONG MACHINERY is a professional machine manufacturer dedicated to designing and developing the high technology plastic machine with more than 20 years' experience. Our developing concept is quality first, service foremost, and we are looking forward to cooperating with you for a bright future.