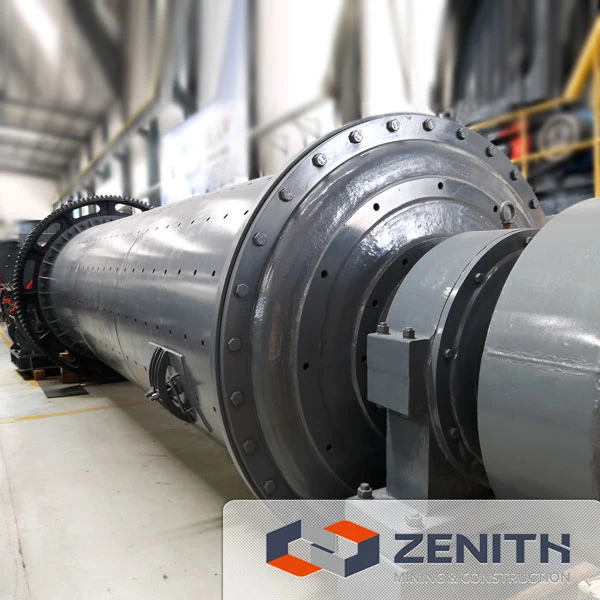

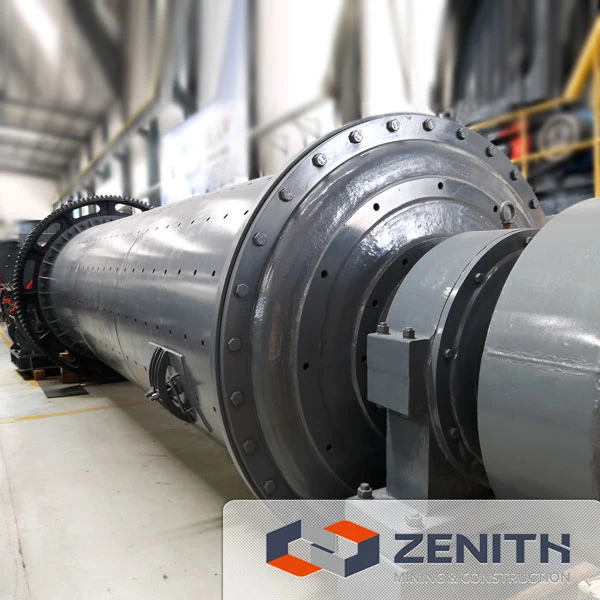

mineral powder grinding mill Introduction:

The mineral powder grinding mill is mainly used in grinding the raw materials and end products in cement plant. It is also suitable for various ores and other materials metallurgy, mine, chemical and construction. Besides, it has two forms of milling, one is an open form, and another is a recycle close form equipped with powder concentrator. It is widely applied in many industries and has simple operation.

It has many advantages such as, strong adaptability, continuous production, large crushing ratio, easy to adjust the size of the products. And it is suitable for both dry production and wet production, also can allow the milling and drying processing simultaneously.

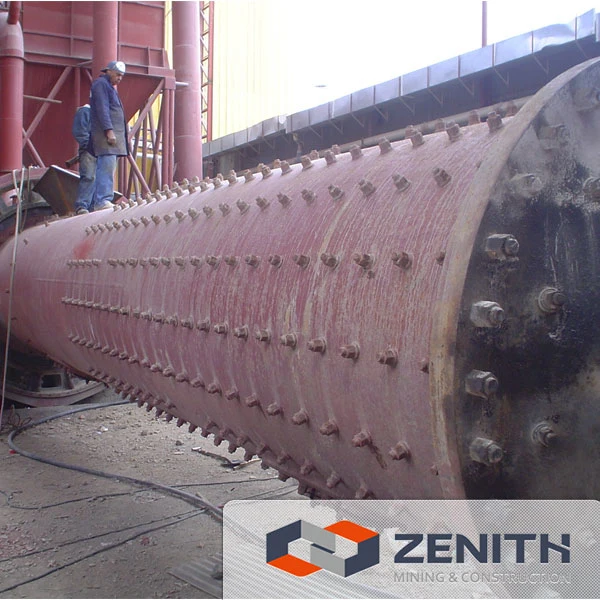

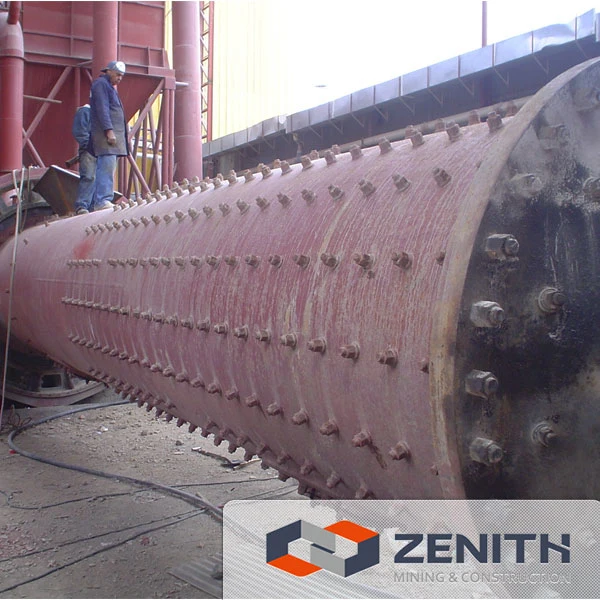

mineral powder grinding mill Structure features:

1.The end cover and the quill shaft adopt monobloc casting

2.The end cover and discharging system are streamlined to cut down wind resistance, enlarge the effective volume and make easy to discharge materials, increase the production.

3.Single silo structure, and adopt different structure of liner plate in different section, ensure the high efficiency.

4.Heat preservation measures ensure the drying ability reach 6%-8%

5.Negative pressures; efficiently prevent the phenomenon of powder leaking.

6.Reserved DCS interface; meet the demand of concentrated control.

mineral powder grinding mill parameters:

Wet Raw Mill

Wet Raw Mill

| Specification (Dia×Length) | Rotating speed (r/min) | Feed size (mm) | Capacity (t/h) | Grinding media load (t) | Main motor | Main reducer | Weight(t) | |||

| Model | Power(kw) | Rotating speed (r.p.m) | Model | Reduction ratio | ||||||

| φ2.2×7 | 21.4 | ≤3 | 20~25 | 31 | YR148-8 | 380 | 740 | ZD70-9 | 5 | 49 |

| φ2.2×13 | 21.6 | ≤25 | 33~37 | 58~60 | YR630-8/1180 | 630 | 740 | MBY630 | 5.6 | 53.4 |

| φ2.4×13 | 21 | ≤25 | 45~50 | 65~70 | YR800-8/1180 | 800 | 740 | JDX710 | 5.6 | 131 |

| φ2.6×13 | 20 | ≤25 | 45~46 | 80t(max) | YR1000-8/1180 | 1000 | 740 | TDX800 | 6.3 | 153 |

| φ6.2×6.4 | 18.5 | ≤25 | 32~41 | 86~90.5 | TDMK1000-36 | 1000 | 740 | 134 | ||

Dry Raw Mill

| Specification (Dia×Length) | Rotating speed (r/min) | Feed size (mm) | Capacity (t/h) | Grinding media load (t) | Main motor | Main reducer | Weight(t) | |||

| Model | Power(kw) | Rotating speed (r.p.m) | Model | Reduction ratio | ||||||

| φ2.4×8 | 20.91 | ≤25 | 25~28 | 39~42 | JRQ1512-8 | 570 | 740 | ZD80-9 | 5 | 76.4 |

| φ2.4×10 | 20 | ≤25 | Open circuit 27~30 Closed circuit 38~40 | 50 | YR710-8/1180 | 710 | 740 | JDX630 | 5.6 | 111 |

| φ2.4×11 | 21 | ≤25 | Open circuit 41~42 Closed circuit 46~48 | 62~65 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 125 |

| φ2.4×12 | 21 | ≤25 | Open circuit 40~42 Closed circuit 45~48 | 63~65 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 127 |

| φ2.4×13 | 21.5 | ≤25 | 48~51 | 68~72 | YR800-8/1180 | 800 | 740 | MBY710 | 6.3 | 131 |

| φ2.6×8 | 20 | ≤25 | 30~35 | 54 | YR630-8/1180 | 630 | 740 | JDX630 | 5.6 | 135 |

| φ2.6×10 | 20.91 | ≤25 | 45~46 | 80 | YR1000-8/1180 | 1000 | 740 | JDX710 | 6.3 | 136 |

| φ3×9 | 19.13 | ≤25 | 50~55 | 76~80 | YR1000-8/1180 | 1000 | 740 | JDX800 | 6.3 | 145 |

| φ3.2×7 | 18.25 | ≤25 | 50~52 | 58 | YR1000-8/1180 | 1000 | 740 | MBY800 | 6.3 | 140 |

| φ3.2×9 | 18.3 | ≤25 | 60~70 | 90 | YR1250-8/1430 | 1250 | 740 | JDX900 | 7.1 | 175 |

| φ4.6×10+3.5 | 15 | ≤25 | 195 | 190 | 3550 | 740 | JS150-B-F | 476 | ||